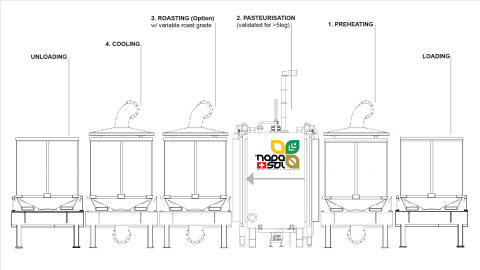

ROAST FINISH - AIR ROASTING MODULE

Roast Finish is a patented process which allows roasting full bins of bulk products.

Bins move automatically through all stages of the process:

- Preheating Platform: Product is pre-heated with warm air to a specified temperature, prior to automatically moving to the pasteurization chamber

- Pasteurization Chamber: The ambient air inside the chamber is evacuated by pulling a vacuum. Once the pressure target has been reached, saturated steam is injected to perform the kill-step on the entire surface of the product.

- Roasting Platform: The warm and safe product post-pasteurization is autotically moved to the roasting platform, where the product is homogeneously roasted with warm air to the specific roasting profile (light - dark, light - strong)

- Cooling Platform: The pasteurized and roasted product is actively cooled with HEPA filtered air to a temperature suitable for further processing.

Advantages

The ROAST Finish roasting solution offers the following advantages:

- Kill step is already completed prior to roasting. Temperature applied exclusively to develop nuanced flavors

- Process steps are controlled through product specific recipes, fully documented, and CFR 21 compliant

Applications

The Roast Finish roasting solution is ideally suited for:

- Nuts

- Seeds